OneEQ Vice President Irene Bickell explains why IPD is becoming an essential part of hospital construction

When people think about the future of healthcare, they typically think about new technologies, procedures and tests that will speed healing times, cure complex illnesses, and enhance the overall patient experience. Certainly, those advancements will change how physicians work and how patients are treated, but I would argue that healthcare is being revolutionized by a process put in place long before a hospital’s first MRI machine is purchased: Integrated Project Delivery, also known as IPD. To be clear, IPD isn’t a new concept, but as hospitals and healthcare facilities become more and more complex, IPD is becoming the way forward for any value-conscious organization.

What is IPD?

Just as it sounds, in healthcare, IPD is a process for designing and constructing hospitals that integrates the entire team from the very beginning, including the owner, architect, engineer, general contractor, equipment planners, interior designers, practitioners, and even the BIM and Revit teams. The financial structure is integrated as well, with every “trade partner” (i.e., the architect, engineer, equipment planners, etc.) taking on risk.

In practical terms, that means everyone on the team is working toward a common goal and, together, almost operating as their own company, although they remain employed by their respective organizations. As anyone in construction can tell you, the relationship between these entities isn’t always amicable on a non-IPD project. Once the team makes the shift from an adversarial relationship to a cooperative one, true innovation, cost savings and excellence become the new goals.

Benefits of IPD

At OneEQ, we are strong proponents of IPD and we truly think it’s the way most future hospitals will (or should) be built. IPD is not ideal for every project, but it has some very clear benefits for most healthcare organizations.

Value and cost savings. Our experience backs up the research that shows when trade partners are treated as one team from the beginning, we head off potential problems before they become expensive change orders that affect the construction schedule, all of which can affect the bottom line of a project. Each trade partner’s profit is at risk, which is a powerful motivator to make sure everyone is bringing their best, value-driven ideas to the table.

Collaborative Attitude. IPD means more teamwork and a better work environment where innovative ideas can thrive. When a challenge comes up, rather than having one organization blame another or avoiding litigation as the main goal, we come together as a team to figure out the best person or sub-team to solve the issue. Finally, healthcare is data and operationally focused and IPD brings us closer to a data-driven, performance-based compensation model for the entire design, planning and construction team.

A Cutting-Edge Structure for Cutting-Edge Hospitals. Most of the organizations we work with are already known as leading research institutions and they want it to stay that way, which necessitates innovation and vision. Through the IPD process, the team can put the best people to work on the toughest challenges, using their expertise to implement new ideas and technologies. In a typical construction project, different teams and experts are brought on at different points of the process, making it more challenging to implement new ideas along the way.

Coordination is a Breeze. This may sound like an exaggeration, but as equipment planners, the value of coordinating hundreds of thousands of moving parts with a cooperative team is incalculable when compared to coming into a project in the final year and dealing with a multitude of contractors, vendors and project team members; if we’re all working toward a common goal, that process naturally goes much more smoothly.

Limitations of IPD

Although IPD is an excellent way to build a hospital, everything has drawbacks.

Every member of the team is involved from the very beginning. This is a major advantage for the most part, but from our perspective as equipment planners, it can be a double-edged sword; we can prevent issues by offering our expertise from the beginning, but because these projects can last for 5-10 years, it can be challenging if not impossible to predict what technology will be available when the hospital opens for patients. We typically solve this issue by including time in the project schedule to re-evaluate planned equipment and technology and assess what new technology would benefit the hospital.

Some owners are reluctant to adopt IPD. The risk structure isn’t as familiar and it can be challenging to explain. Legally, it can be difficult for state owners to adopt this structure.

Your profit is at risk. The nature of IPD means that every trade partner’s profit is at risk. By being efficient, thoughtful and coordinated, everyone stands to make a healthy profit, but there’s always the possibility that the opposite could happen.

The Proof is in the IPD Pudding

OneEQ has completed a number of hospital projects using the IPD model. For us, as equipment planners, the value is significant; for our clients, the value in the tens of millions of dollars, if not higher.

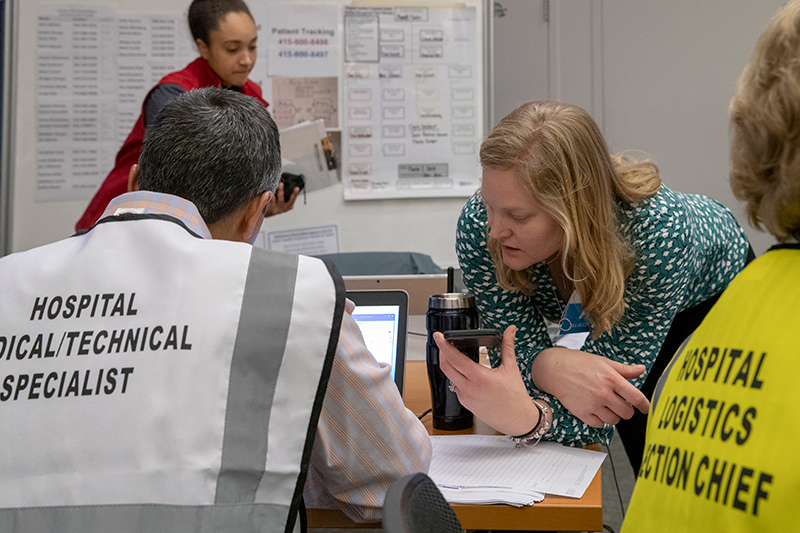

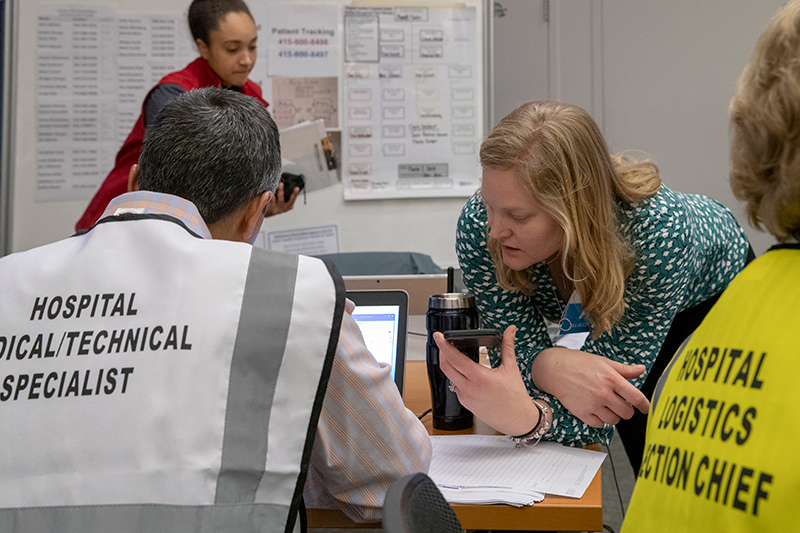

One of OneEQ’s most recent examples is CPMC Van Ness in San Francisco. The hospital takes up an entire city block in the Tenderloin and had a budget of $2 billion. Their were a number of challenges from the beginning, including a very constrained site surrounded by extremely busy roads. As the equipment planning team, our responsibilities included the logistic and deployment of all the medical equipment. We had to figure out how to deliver equipment in large semi-trucks, in heavy traffic, with a very small loading dock. By coordinating with the rest of the IPD team through the process, we created a number of unusual solutions—we utilized an off-site warehouse and broke down everything and disposed of trash and packaging outside of the city to save significant costs. We then brought everything in on smaller trucks and implemented a complex RTLS (Real Time Location System) system for the 35,000 pieces of equipment.

Our team worked with the owner and other vendors to tag everything from the warehouse, where it could then be tracked and pinged as it went from the warehouse to the dock and from the dock to its location within the hospital. This streamlined process omitted the typical manual process, saving about 15-20 minutes per piece. With 35,000 pieces, the client estimates it reduced the project cost by about $150 million.

Now that the hospital has opened its doors, the system continues to save the hospital money by eliminating the time it takes to find moveable equipment—for carts and other equipment on wheels, staff can simply look up an item’s location on the RTLS system instead of walking the halls to find it.

The RTLS process put in place is just one very specific example of how the IPD process saved the project money and continues to make CPMC Van Ness a technologically advanced hospital for a diverse urban community. Each time OneEQ participates in an IPD process, we have seen several of these types of incremental changes that have had a huge impact on the final project—it’s the reason IPD leads to innovation and why more owners and construction teams will fight for IPD in the coming years.

How equipment planners—backed by Attainia’s powerful medical equipment planning platform—can manage change to a positive clinical and financial outcome during healthcare construction and renovation projects.

How equipment planners—backed by Attainia’s powerful medical equipment planning platform—can manage change to a positive clinical and financial outcome during healthcare construction and renovation projects.