Necessity may be the Mother of Invention, but Technology is the Midwife.

Sometimes big projects come down to small details

By Steve Juett PE, LEAN GB, LEED Green Associate

Senior Associate Vice President

We’ve all been there: standing in front of the room with our new computer, about to give that career-defining presentation, everyone staring expectantly, waiting. But you, unable to connect to the projector because of that trivial piece of tech you forgot to bring, stand motionless. Helpless. Sweating. Time moves to a dream tempo. Someone coughs. Your career goes into a death spiral because you forgot the dongle. For want of a simple piece…

Well, such was almost the case in a recent OneEQ commission for Stanford Health Care at 500 Pasteur Drive, a new 824,000-SF revolutionary hospital designed to accommodate advances in medical technology, increase capacity needs and transform the way that patient care is delivered.

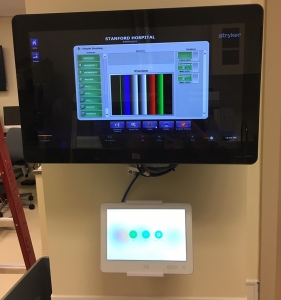

OneEQ worked closely with SHC to identify an integrated network of systems to support their mission and deliver next-generation technology. And to do so as close to the patient as possible and as efficiently as possible. At 500P, we specified an OR video conferencing system by Stryker Communications, which allows clinicians to connect within the operating room to other ORs, pathology for lab verification, surgeons for intraoperative consultations and to auditoriums for education. The client required the system be compatible with their in-place infrastructure, a Cisco CODEC, which seems only reasonable. The problem, though, was that Stryker’s system does not use the same protocols as Stanford, a situation not unlike you standing in front of the room unable to connect to the projector.

So, we came up with a work-around: A simple touchpad that sits on the counter and provides a friendly, clear user interface, marrying the Stryker system with the Cisco system. But the client preferred the touchpad on the wall, another request that also seems reasonable but would have significant implications: every wall mount kit available on the market requires opening the wall to install recessed back boxes and conduit. Opening the wall meant that the task would need a submission to California OSHPD and updated architectural construction drawings.

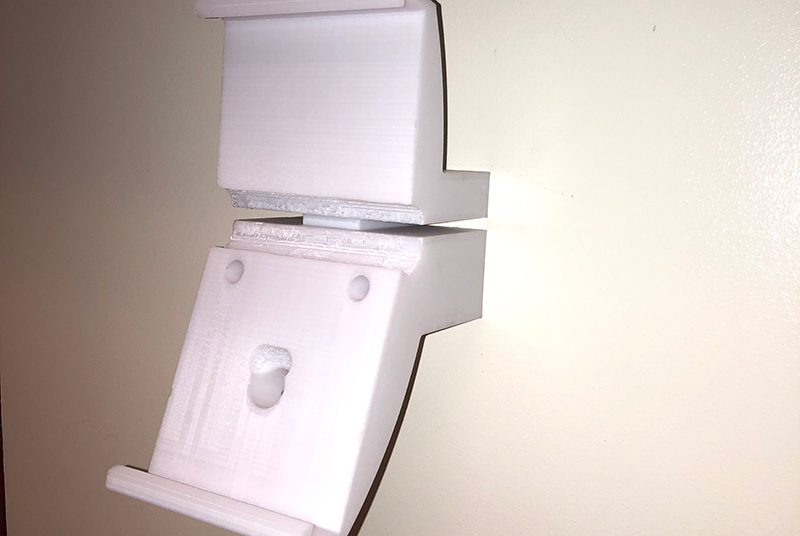

So, we came up with a work-around to the work-around. Thanks to the magic of the Internet, we located a 3D touchpad modeling company that offered a clam-shell wall bracket very close to what we needed. We acquired a model of the piece and adapted it the specifications of the touchpad. With our model in tow, we identified a local fabricator who was able to 3D print it as a low-cost Beta version in a simple polymer, allowing us to test the piece on site and clear it with the client. Once approved, the piece could be produced at scale in various plastics or metals.

After a few simple modifications, the new piece was a success. It allowed us to mount the touchpad exactly where the client wanted it without opening walls and running conduit, a simple triumph that saved time, money and jurisdictional review.

Sometimes we get tripped up by the small things, especially when we extrapolate them into larger problems. The wall mount, as trivial as it may seem in a project with a medical equipment budget of $200 million on 37,000 items, meant a lot to our client and the way they work. I’d like to think that it made a difference to someone’s life. And I’d like to think that we bring that level of creativity and ingenuity to every OneEQ project.

Steve Juett makes hospitals work. Sure, Steve knows tech—from clinical systems and medical equipment to infrastructure, communications and patient monitoring—but Steve also knows how all of this comes together, connects, saves lives. And that makes all the difference.